Table of Contents

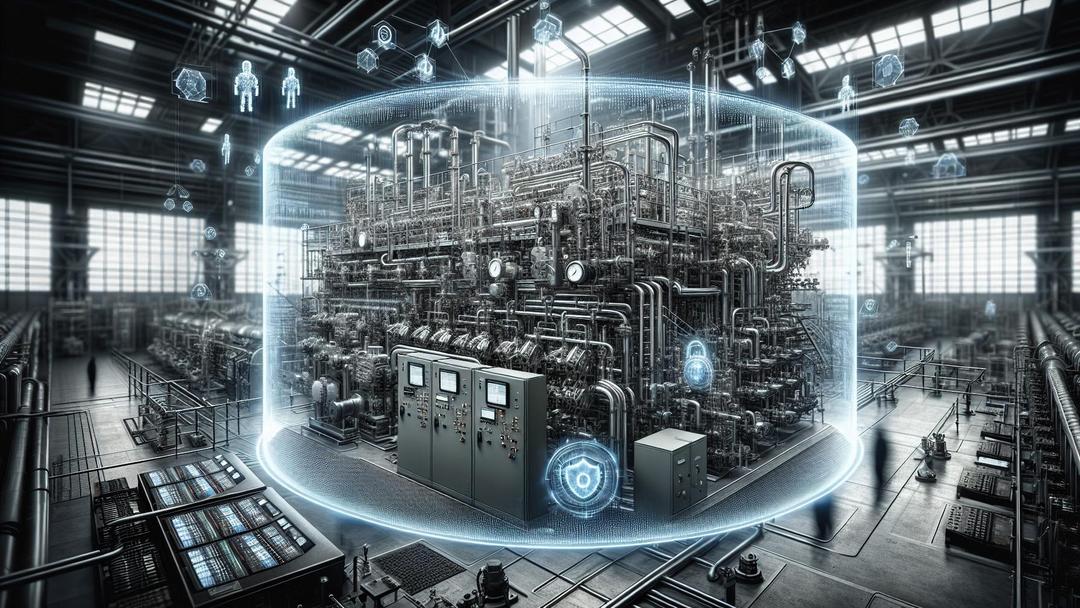

Critical ICS Patches from multiple industrial control system vendors landed this week, closing high severity vulnerabilities that threaten operational technology environments across energy, manufacturing, and infrastructure.

The updates cover widely deployed PLCs, engineering software, networking equipment, and power automation platforms. Rapid patching can cut the risk of downtime, safety events, and compromise.

Below is what changed, why it is urgent, and how to prioritize safe deployment in production.

Critical ICS Patches: Key Takeaway

- Act now. Critical ICS Patches from major vendors remediate high risk flaws that could disrupt operations or safety if left unpatched.

Tools that support ICS and OT hardening while you patch:

- Tenable Vulnerability Management: Discover and prioritize risks across IT and OT assets.

- IDrive Backup: Ransomware resilient backups for business continuity.

- Auvik Network Monitoring: Map, monitor, and alert on network changes in real time.

- 1Password Business: Strong credential security and access controls.

- Passpack: Team password management built for audits and compliance.

- EasyDMARC: Lock down email channels and reduce phishing risk.

- Tresorit: End to end encrypted file sharing for sensitive OT documents.

Why These Critical ICS Patches Matter Now

Industrial systems focus on reliability and safety, but long life cycles and complex supply chains make patching difficult. Threat actors exploit that gap. Critical ICS Patches often fix remote code execution, authentication bypass, and insecure defaults that adversaries target.

According to this detailed report on the latest releases, fixes span vendors common in energy, manufacturing, and building automation.

Many vulnerabilities affect engineering workstations, HMIs, protocol gateways, and PLC firmware, components that connect IT and OT. Critical ICS Patches should be assessed and staged quickly within safety cases and production schedules.

Critical ICS Patches

The latest Critical ICS Patches span several product lines. While vendor advisories list exact affected versions, common risks include:

- Remote code execution that enables logic manipulation or controller crashes

- Privilege escalation that allows unauthorized configuration and safety changes

- Information disclosure that aids reconnaissance and lateral movement

Review vendor bulletins and cross reference the CISA ICS Advisories and the NIST NVD for CVE details, CVSS scores, and exploitability notes. For threat modeling and compensating controls, consult the MITRE ATT&CK for ICS matrix.

Vendor Highlights and Patch Priorities

Siemens, Schneider Electric, Rockwell Automation, ABB, and Phoenix Contact released updates. While environments vary, a practical sequence is:

- Patch exposed interfaces first, including engineering stations, remote access tools, and networked HMIs

- Address PLC firmware where remote code execution or memory corruption is possible

- Update protocol converters and gateways that bridge IT and OT traffic

When scheduling Critical ICS Patches, document pre and post change states, capture backups, and verify logic signatures.

If you must delay, apply mitigations such as strict allowlisting, network segmentation, and read only engineering modes where feasible.

Safe Deployment in Production Environments

Because downtime is costly, Critical ICS Patches benefit from a tiered rollout. Test in a lab, pilot on non critical lines, then expand. Validate interdependencies, especially between firmware, drivers, and engineering tool versions.

Follow vendor hardening guides and align controls with ISA/IEC 62443 zones and conduits.

Maintain momentum by tracking monthly cycles. For broader context, see these related reads on December ICS Patch Tuesday updates and how Microsoft patches multiple zero day bugs, both reinforce the value of consistent, timely updates alongside Critical ICS Patches.

Risk Reduction Beyond Patching

Critical ICS Patches are one layer in a defense in depth program. Combine them with:

- Asset inventories that identify firmware and software versions across OT

- Network monitoring to detect anomalous traffic and suspicious command patterns

- Access control, MFA, and strong credential management for shared workstations

- Immutable backups and incident response runbooks for rapid recovery

For architectural resilience, many operators are evaluating Zero Trust architectures that limit blast radius if a device is compromised, even when Critical ICS Patches cannot be applied immediately.

Operational Implications for OT and IT Teams

Advantages

Applying Critical ICS Patches reduces the likelihood of process disruption, ransomware impact, and safety incidents. It also strengthens compliance posture and meets common regulator or insurer expectations. Consistent patching shortens mean time to remediate and builds confidence across engineering, security, and operations teams.

Disadvantages

Patching OT introduces change risk, including unintended logic behavior or vendor compatibility issues. Access windows are limited, and reboot cycles can be long.

Where Critical ICS Patches are not immediately deployable, teams must rely on compensating controls and close monitoring, efforts that require time, budget, and specialized staff.

Harden your environment while you schedule Critical ICS Patches:

- Tenable OT Security: Visibility and risk insights for industrial assets.

- IDrive Backup: Air gapped options to recover fast from attacks.

- Auvik Network Monitoring: Baseline traffic and catch anomalies early.

- 1Password Business: Secure shared credentials in OT and IT.

- Passpack: Enforce least privilege and auditable access.

- EasyDMARC: Reduce email borne threats to operations teams.

- Tresorit: Share patch runbooks securely with vendors.

Conclusion

Industrial defenders must manage risk without disrupting operations. This week’s Critical ICS Patches provide a direct way to reduce exposure from known, fixable flaws.

Coordinate across engineering and security to test, stage, and deploy safely. Where patching must wait, tighten segmentation, strengthen credentials, and expand monitoring to reduce attack surface until Critical ICS Patches are applied.

Build a disciplined cadence of advisories, inventories, testing, and verification so each new wave of Critical ICS Patches becomes routine rather than a scramble.

Questions Worth Answering

Which systems should I patch first?

Prioritize internet exposed components, engineering workstations, HMIs, and any device with remote code execution risk. Then address PLC firmware and protocol gateways.

What if downtime prevents immediate patching?

Use compensating controls, including network segmentation, strict allowlisting, MFA, read only engineering modes, and enhanced monitoring until maintenance windows open.

How do I verify patches did not break processes?

Test in a lab, pilot in non critical zones, capture backups, validate logic signatures, and document pre and post change states. Monitor KPIs closely after deployment.

Are these vulnerabilities being exploited?

Not all are known to be exploited, but attackers frequently target OT. Check vendor notes, CISA ICS advisories, and the NVD for updates.

How often should I review ICS advisories?

Weekly at minimum, with emergency reviews for high severity alerts. Incorporate advisories into change control and incident response workflows.

What frameworks help guide OT patching?

Follow ISA/IEC 62443 principles, vendor hardening guides, and map risks with MITRE ATT&CK for ICS to select controls.

Does Zero Trust help in OT?

Yes. It limits lateral movement and reduces blast radius when immediate patching is not possible, complementing Critical ICS Patches with robust access controls.

About Siemens

Siemens is a global technology company with a significant portfolio in industrial automation and digitalization. Its hardware and software support manufacturing, energy, and infrastructure systems worldwide.

Siemens ProductCERT regularly releases advisories and updates that improve security across OT environments.

Explore more tools:

Plesk,

CloudTalk,

Trainual.